The SMART way to sterilise handpieces

In the third in our series on the SMART way to maintain and decontaminate dental handpieces, decontamination consultant Mark Beckwith discusses the sterilisation of handpieces and the pivotal role played by the right choice of autoclave.

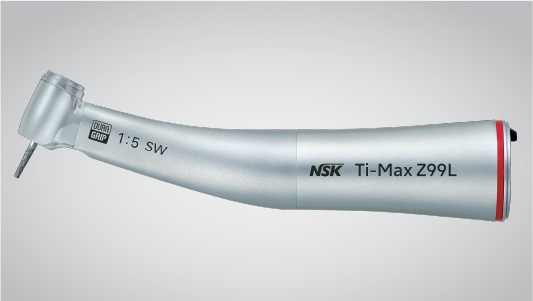

Dental handpieces are the cornerstone of dental treatment and oral surgery, designed to perform every task from a routine filling or prophy appointment through to root canal, implant or restorative treatments on a daily basis. Investing in quality handpieces that are designed to provide years of service makes perfect sense, but only if these precision-engineered instruments are decontaminated and maintained with meticulous care after every use.

However, by the very nature of the work they do, dental handpieces are routinely contaminated with blood, saliva and biological residues, making them a potential transmission risk of a host of bacterial and viral infections, including COVID-19, and blood-borne diseases including Hepatitis B, C and HIV.

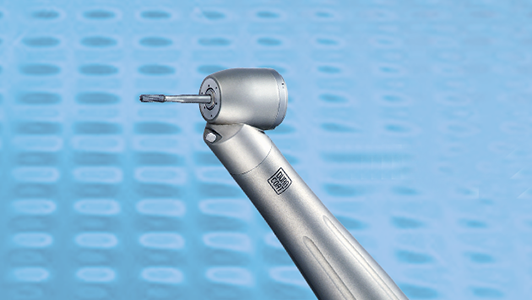

While it’s relatively easy to see and remove contamination on the external surfaces of handpieces after use in the surgery, ensuring that the hidden internal surfaces and hollow channels (lumens) deep within the handpiece chamber are scrupulously decontaminated can be the major challenge.

The SMART way forward

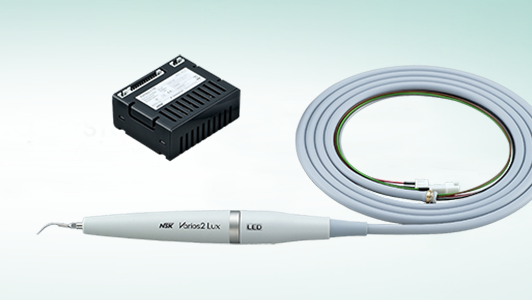

The NSK SMART3 handpiece decontamination protocol is designed to offer a safer, measured and more affordable method for decontaminating handpieces, one that is reproducible and time-saving. By adopting a Smart3 approach you will ensure effective decontamination and sterilisation of all your instruments, especially your handpieces, as well as maintaining peak performance and maximum lifespan of your valuable instruments. The protocol consists of three key steps – Cleaning, Lubrication and Sterilisation. Here we look more closely at the sterilisation stage of the NSK SMART3 process, including the pivotal role of the autoclave. The role of steam sterilisation is the essential next step after cleaning and lubrication for the reprocessing of handpieces that have become contaminated with saliva, blood or other biological fluids. The aim of sterilisation is to break the chain of potential cross-contamination between patients by killing microorganisms, including any dangerous viruses, bacteria and fungal spores that may otherwise cause infection or disease. The recommended method for sterilisation of hollow handpieces, such as turbines and contra-angles, is by using the correct, validated autoclave cycle that delivers saturated steam, under pressure at the highest temperature compatible with the load, typically 134-137°C for at least a 3-minute holding time.

Sterilisation requires direct contact between saturated steam and every surface of the instrument. However, because of the complexity of hollow instruments including dental handpieces (and where instruments are being processed in sealed sterilising pouches), effective steam penetration and sterility will be compromised by the presence of air within the instrument or sterile packaging. As a result, it is imperative all air is actively removed from within the chamber and load when processing anything other than solid, unwrapped instruments (ref: HTM 01-05 – 4.5). The process of active air removal can only be achieved in an autoclave that creates a state of vacuum prior to sterilisation. This is achieved by the use of an autoclave that uses a vacuum pump to forcibly remove the air, as opposed to a non-vacuum autoclave which relies on gravity or downward displacement by steam to passively remove the air from the chamber and load.

Autoclave cycle types and guidance

There are three types of autoclave cycle: N, S and B which differ in the types of loads that can be sterilised and whether or not items can be wrapped or pouched during sterilisation.

Type N autoclave cycles rely on displacement by steam to achieve air removal. Research has shown (Winter et al.) they do not reliably sterilise hollow or pouched instruments, making them only suitable for unwrapped or solid items.

Type S autoclave cycles have been defined by the manufacturer to take specific loads through a sterilisation process. Where stated loads include handpieces and pouched instruments. These autoclaves employ vacuum assisted, active air removal and should only be used in strict accordance with the manufacturer’s instructions.

Type B autoclave cycles meet a defined standard i.e. EN13060. These autoclaves almost always employ vacuum pumps to effect active air removal and steam penetration, making them suitable to process a wide variety of load types – hollow, air retentive and packaged loads including hollow instruments in sealed packaging.

In terms of dental guidance, there has always been a question of which type of autoclave cycle should be used to sterilise dental handpieces. This has tended to revolve around the question of whether steam can penetrate a lubricated handpiece and as such, guidance tends to suggest that sterilisation is unlikely to be achieved, whatever cycle type is used.

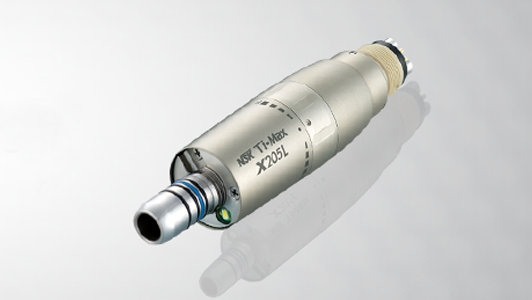

However, if a handpiece has been correctly cleaned and lubricated and excess solution and lubricant is purged from the instrument prior to sterilisation, as is the case when using an automated handpiece cleaning and maintenance unit, then as long as all the air has been removed, steam will be able to penetrate the instrument and take it through a sterilisation process. This is why either the appropriate S or B type vacuum autoclave cycle must always be used to sterilise handpieces, without compromise.

Sterilisation

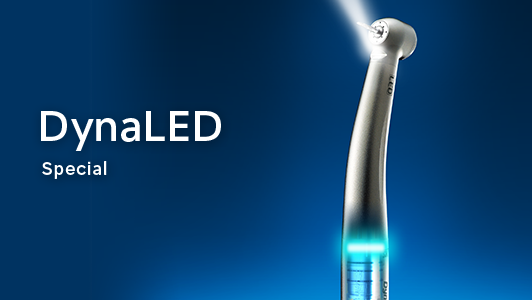

Infection control will continue to remain a top priority as dental teams adjust to new working practices in light of COVID-19. A fast and efficient instrument sterilisation process is vital in today’s busy practices, so an autoclave with quick cycles, proven reliability and ease of service is key.

NSK’s iMax S and iClave plus vacuum autoclaves have been developed to sterilise all instruments, especially dental handpieces. The utilisation of a thermally efficient copper chamber results in improved performance, offering faster, more efficient cycles compared with traditional stainless steel chambered autoclaves of an equivalent size and capacity. And, by employing enhanced thermo-dynamic drying as a result of the improved efficiency of the copper chamber – instruments are better protected from corrosion, discoloration and recontamination, and the iMax S and iClave plus autoclaves from improved levels of reliability and serviceability – owners will benefit from in an ongoing reduction in instrument and autoclave maintenance costs.

Stay SMART

As the UK’s market leader in handpiece and decontamination technology, NSK is committed to improving the standards of handpiece decontamination, especially in light of the heightened risks posed by transmission of harmful pathogens, particularly by asymptomatic patients.

The NSK SMART3 handpiece decontamination protocol discussed in this series of articles makes the three crucial decontamination steps of cleaning, lubrication and sterilisation Safer, Measured, Affordable, Reproducible and Time-saving. Reducing the risk of manual error and inconsistencies by advocating the use of equipment which has been specifically designed for each part of the decontamination process ensures not only that best practice can be achieved but that it can be reproduced every single time.