- AIR TURBINES

- CONTRA-ANGLES

- CLINICAL MICROMOTORS

- MOBILE DENTISTRY

- ORAL HYGIENE

- ENDODONTICS

- SURGICAL

- DENTAL LABORATORY

- HYGIENE & MAINTENANCE

- News

- Courses & Events

- Ikigai Webinars

- Ikigai Enhance (Live Training)

- Online CPD

- Articles

- Podcasts

- Photo Gallery

- Varios Combi Pro

- Varios Series

- Ultrasonic Scaler Tips

- Ti-Max S970/AS2000

- Air Scaler Tips

- Perio-Mate

- Prophy-Mate neo

- iProphy

- Prophylaxis-

Conta-angles - Varios 170

- Global Site

Choose your country or region.

If your country is not on the list, please visit our Global site -

Americas

-

Europe, Middle East

-

Asia Pacific

-

Oceania

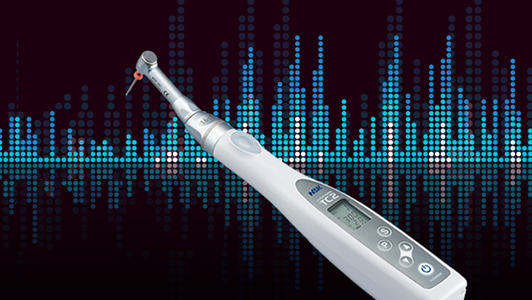

GO ELECTRIC

Turbine vs Electric

Air turbines (traditional high speed handpieces) can be small, lightweight and rotate at high speeds, but torque can vary and noise levels are high.

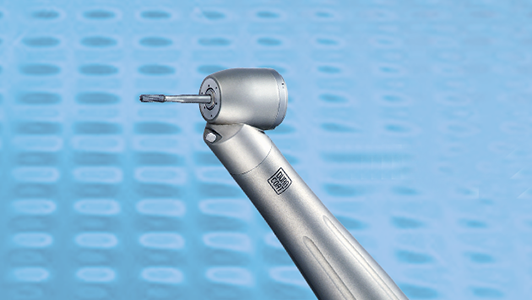

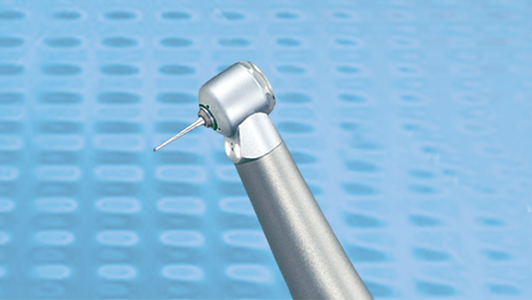

Electric driven, speed increasing contra-angles not only do everything a turbine does using the same FG burs, they provide a consistent torque from the micromotor that does not decrease with resistance and higher load with no loss of power as they come in contact with the tooth.

Electrically driven instruments are well-known for their flexible functionality and for operating at vastly reduced noise levels with reduced vibration for added patient comfort. Thanks to the torque control they provide a smooth and more precise cutting action that is generally considered to be superior to that provided by an air turbine.

“For restorative dentistry I always rely on the Ti-Max Z95L contra-angle which is second to none. What’s so good about the Ti-Max Z95L is that you can enter the speed of the handpiece into the control terminal. When you apply pressure onto the handpiece, the torque is so superior it allows you to cut far more accurately with a lot more tactile feedback of what’s going on, whereas with a turbine I find there’s little tactile sensation at all.”

“We do a lot of close magnification work in practice and I find the Ti-Max Z95L operates with very little vibration and delivers of level of control not replicable with a turbine.”

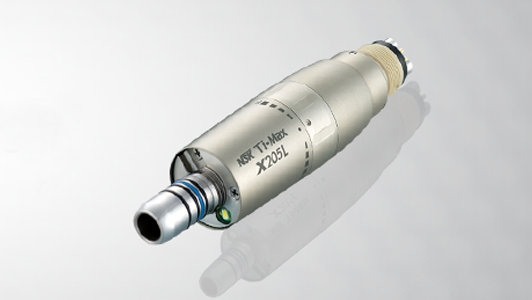

Easy integration for complete control

Electric micromotors are the driving force behind speed increasing handpieces and can be fully integrated into the delivery system of most new and existing dental chairs.

They can be retro fitted by an engineer or come as an option when buying new chairs. Controlling the specific speed and torque of micromotors within existing platforms is made easy thanks to built-in control pads.

The way forward

Speed increasing handpieces generate less aerosols compared to high-speed turbines. To reduce aerosols further the Ti-Max Z95L and Ti-Max Z45L are fitted with the world’s first two-way spray technology unique to NSK allowing clinicians to switch between a water/air mix and water jet only with just a twist of the switch. Plus they have the additional benefit of a non-retraction valve that prevents suckback/contamination of the water line.

When extra safety is needed the water jet provides maximum protection while still offering optimum cooling, then when conditions allow switching back to mist is simple. No equipment modification is needed, putting control back in clinicians’ hands.

How do I Go Electric?

- Choose an NSK electric micromotor as an option on a new chair

- Choose a portable version that attaches to your chair, which plugs and plays eg NLX nano Portable

- Retro fit a NSK electric micromotor to your existing cart

What NSK need to know for a retro fit. The brand of chair/cart you have. A picture of the cart itself. And an idea of where the control panel should sit to the right or left of your cart, based on space.

Speak to your local NSK Product Specialist and they can advise too and help you select the options and offer that is right for you. Then we ensure a suitably trained engineer is available either from NSK or a qualified local engineer.

Special Offers

NSK Micromotor Options

- NLX nano – available for built-in kits

- NLX Plus – built-in kits only, also includes rotary endo feature

- NLZ E – portable only, has more torque and includes rotary reciprocating‡ endo features

Micromotors – Portable Options

+ FREE Ti-Max Z95L & NLZ Endo 6:1 contra angles worth £2,031

Built-in Kit Options

At the touch of a button, control your micromotor and/or ultrasonic scaler. All built-in kit options come with built-in kit and will need a qualified engineer to fit (additional cost).

AND GET FREE Ti-Max Z95L SPEED INCREASING CONTRA-ANGLE

Option A. NLX nano micromotor & BUILT-IN KIT * (including MultiPad) RRP £2,387

Option B. NLX plus micromotor (includes Rotary Endo functions) & BUILT-IN KIT* (including MultiPad) RRP £2,871

Option C. Varios170 Lux Ultrasonic handpiece (tip options for scaling, perio, endo & restorative procedures) + BUILT-IN KIT* (including MultiPad) RRP £1,553 (Y1004145)

Option D. Option A + C RRP £3,781

Option E. Option B + C RRP £4,238

Options for Speed Increasing Contra angles

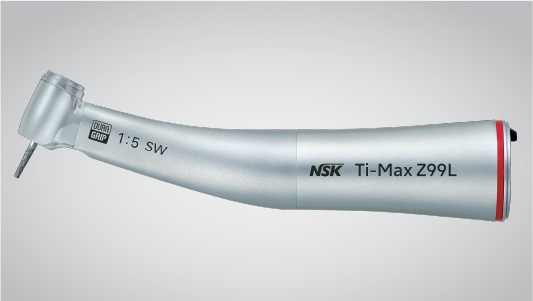

Follow the link, scroll down until you come to 1:5 and compare – Ti-Max (Z95L, Z99L, Z45L, nano95LS) and S-Max (M95L and M95).

For support and advise contact your local NSK Product Specialist.

*Terms and conditions apply. Offers only available through participating dealers. **One per instrument

‡Fits Dentsply Sirona WaveOne® files when used in combination with NLX nano 6:1 contra angle

“The Ti-Max Z95L is perfect as the design offers improved visibility through the reduction of head and neck size and runs with almost no vibration.”