The SMART way to lubricate handpieces

In the second in our series on the SMART way to maintain and decontaminate dental handpieces, NSK’s decontamination manager, Mark Beckwith, explains why lubrication is such an essential step in maintaining these essential, precision-engineered pieces of equipment.

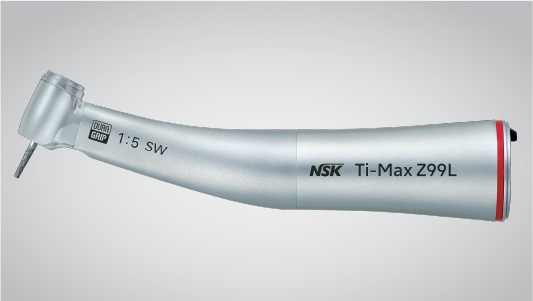

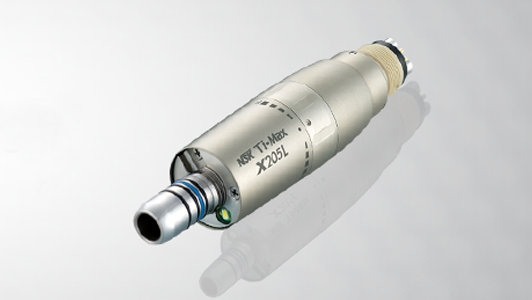

The introduction of both low and high-speed dental handpieces, including air turbines and speed increasing contra-angles, has transformed dental treatment and overall patient care in recent years. Their use however, especially in light of the COVID-19 pandemic, has been subject to controversy, not just in the risks posed by aerosols generated during dental procedures, but in their potential for the spread of harmful pathogens if they are not cleaned, lubricated and go through a sterilisation cycle with meticulous care after every use.

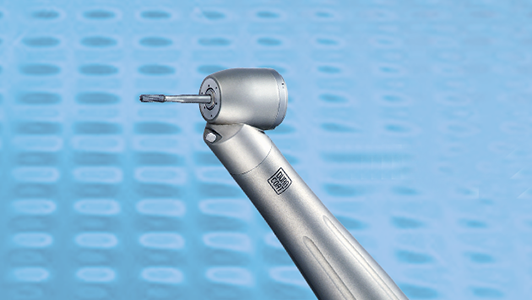

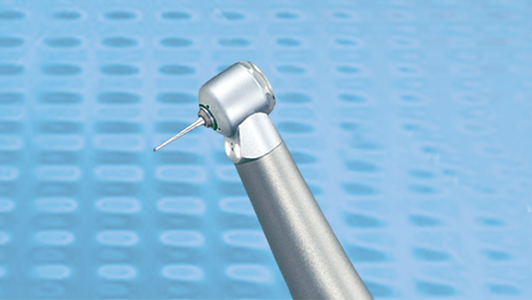

The effective decontamination and sterilisation processes for precision-engineered handpieces remains a challenge, notably the cleaning of hidden internal surfaces and hollow channels (lumens). Concerns centre around the accumulation of debris and bodily fluids including blood and saliva, fragments of restorative materials as well as microorganisms from dental unit waterlines and airlines within the intricate working parts, gears, and turbine blades.

The aim of the cleaning process is to ensure that surfaces are free of debris and matter, so that sterilisation can be effective. Any remaining debris will act as a barrier to steam penetration, especially if it’s baked onto surfaces as a result of previous exposure to the high temperatures associated with steam sterilisation. It’s important to remember that if something is not clean it cannot be sterilised.

Look SMART

After efficient cleaning and prior to sterilisation, lubrication is the next vitally important step in ensuring handpiece functionality and longevity. Here we take a closer look at the lubrication stage of the NSK SMART3 process and the benefits of an automated system to ensure the effective maintenance of precision-engineered dental handpieces.

Get the balance right

Once a handpiece has been cleaned and thoroughly dried, the internal surfaces and lumens must be adequately lubricated prior to sterilisation, in order to maintain optimum performance. This should be carried out in accordance with the handpiece manufacturer’s guidelines.

As with internal cleaning, a manual process is not always the most effective way to lubricate a handpiece, especially as it relies heavily on the diligence of the operator to ensure the proper steps are taken.

Plus, it can be a messy, inconsistent and time-consuming procedure – residual moisture from the cleaning liquid, which if present can cause emulsification, and excess lubricating oil must be allowed to thoroughly drain from the handpieces at each stage of the process.

Handpieces can be damaged especially from having too little oil as this can result in increased friction within the handpiece and additional wear. If too little lubrication is applied, the handpiece can run dry and seize up, resulting in unnecessary downtime and expensive repair costs.

Automated systems

To avoid the potential pitfalls of manual lubrication, many practices invest in an automated handpiece cleaning and lubrication unit. The adoption of one of these dedicated units is undoubtedly a smart move. It provides for a safer, more measured approach that is affordable, reproducible and time-saving. They dispense the precise amount of lubricant every time, to all parts of the mechanism including internal lumens, and ensure the handpiece is prepared correctly for subsequent sterilisation.

Importantly, such units should also connect to a source of compressed air. This will ensure any residual contaminants, solutions and lubricants will be automatically purged from inside the handpiece at each stage of the cycle, in just a matter of seconds. Units such as the NSK iCare are designed to clean and lubricate up to four instruments at a time, dispensing the precise amount of lubricant required for effective sterilisation. The iCare incorporates a set of nozzles with handpiece specific adaptors to cater for both air turbines and contra-angles from most major manufacturers, making it a versatile and cost-effective investment. This measured, effective and reproducible process means handpieces are turned around faster, inventories are better managed, and the overall process is less prone to human error. Safety first In the current climate it is essential that dental practices maintain the highest standards of instrument decontamination, especially when it comes to handpieces. Every step must be taken to reduce the risk of infection within a practice, especially with latest figures from the Office of National Statistics showing more than 53 per cent of people with COVID-19 did not report any major symptoms compared to 47 per cent who did, underlining the risk of people spreading the virus without knowing they are infected.

The solution

The NSK iCare handpiece oiling and maintenance unit is an ideal and cost-effective way to help ensure effective sterilisation and long term care of handpieces and reduce the potential risks of the spread of infection for both patients and staff.

There is also the NSK iCare+ decontamination unit that incorporates the additional steps of external cleaning and disinfection, proven to provide increased protection when used with the n.cid bactericidal, fungicidal and virucidal disinfection solution.

NSK is world renowned for its innovative development of precision engineered dental handpieces. Now NSK’s equally innovative high-performance decontamination equipment, including the NSK iMax S and iClave Plus vacuum autoclaves, helps practices maintain handpieces in peak condition while also efficiently reprocessing them for safe and reliable use, time after time.