The SMART way to clean dental handpieces

The effective decontamination of handpieces to ensure they are safe to use is essential in the daily running of your dental practice, especially in today’s climate where the risk of transmission of harmful pathogens is greater than ever. Your handpieces are the tools of your trade, hardworking instruments which are relied upon to function flawlessly, delivering the exact amount of power and precision required for each procedure, again and again.

As sophisticated instruments with precision-engineered moving parts they must be decontaminated and maintained with meticulous care, which includes putting them through a thorough cleaning, lubrication and sterilisation process after each use. Failure to re-process your dental handpieces correctly not only compromises safety, but also restricts performance and reduces the lifespan of your investment. Getting it wrong can have a detrimental impact on your practice, both clinically and financially.

Your decontamination team therefore require a robust process and reliable equipment that will help them not only meet, but exceed industry-wide decontamination standards.

Be SMART

The NSK SMART3 handpiece decontamination protocol offers a safer, more measured and affordable process, one that is reproducible and time-saving. This article takes a closer look at the cleaning stage of the NSK SMART3 process and considers how to make this initial step in the decontamination process as SMART as possible.

Start outside

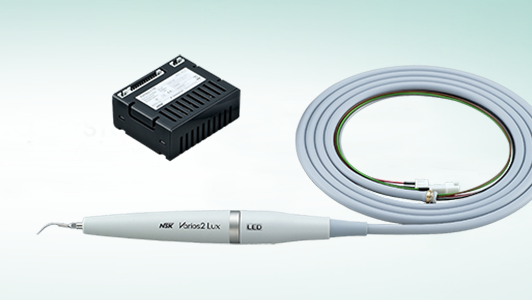

Once they have been brought to the dedicated decontamination area, all contaminants on the external surface should be immediately removed, ideally by processing in an automated unit that has been designed to clean the outsides of handpieces – the NSK iCare+ is ideally suited to this.

Alternatively, external handpiece cleaning can be performed manually, under cold running water using a soft to medium, non-metallic brush. It is vital to remove all obvious signs of matter and debris on the surface of the handpieces, which if not removed can prevent effective sterilisation.

After cleaning by hand, the external surfaces should be disinfected with a good quality disinfectant wipe. Any residue should rinsed off under cold running water, in a separate sink to that used for cleaning, and then be dried with a clean tissue or paper wipe. After a careful, visual inspection, they are ready to be cleaned internally.

On the inside

Cleaning the internal surfaces and lumens of a handpiece is best achieved using an automated device, one designed specifically for this task. The alternative is to use a manual process. However this can be very inefficient and is difficult to reproduce accurately on a consistent basis. It can take considerable time to perfect a workable routine and even the best manual processes can be very messy, especially when it comes to ensuring residual solutions and lubricants have been drained from the handpiece. Furthermore, the ongoing cost of the right consumables can become prohibitive, let alone the cost of employing a dedicated member of the team to undertake what can be a thankless task.

The benefits of automation

In the quest for a more efficient process, many practices now rely on a dedicated handpiece cleaning and lubrication unit such as the NSK iCare to facilitate this level of re-processing. These automated systems have been designed to quickly and effectively remove dirt and debris from the internal workings of dental handpieces, using tried and tested solutions and to deliver the precise amount of lubricating oil in preparation for sterilisation.

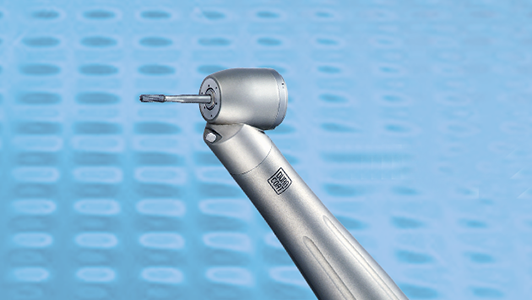

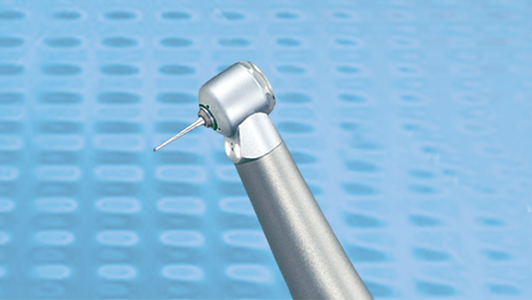

Incorporating a set of nozzles which come with handpiece specific adaptors so they can accept both air turbines and contra-angles, these units can process several handpieces simultaneously in a matter of minutes, saving valuable time. Units from the likes of NSK are compatible with handpieces from most major manufacturers, making them a versatile and cost-effective investment. And, by connecting these units to a source of compressed air, any residual contaminants, solutions and lubricants that could compromise the sterilisation process will be automatically purged from the inside the instruments in a matter of seconds.

Manufacturer support

It’s also smart to find a handpiece manufacturer who will provide support to their customers in optimising their handpiece decontamination process, in the form of instructional videos and resources and specific decontamination training.

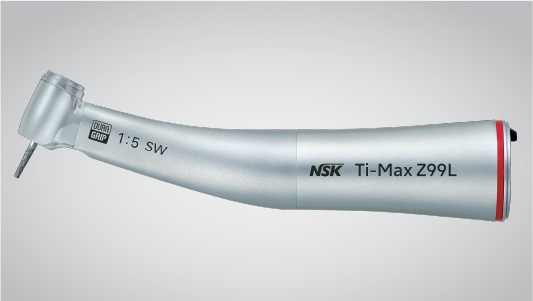

NSK – who manufacture a wide range of dental handpieces and decontamination equipment – offer training to make sure their customers know how to care for and maintain their instruments to get the best performance out of them and maximise their lifespan. Downloads and videos on their website are permanently available for reference and their customer support service is always there to give advice and useful tips about caring for their handpieces.

Look out for the next article in our series on SMART handpiece decontamination which looks in more detail at the essential process of lubrication. Find out more about NSK’s wide range of decontamination equipment here…