The evolution of surgical micromotors

Electric micromotors have long been an essential part of oral surgery where the majority of surgical procedures necessitate a constant speed and controlled torque. Electric micromotors have been around in one form or another since the mid-1970s and brushless motors are now the standard in the dental industry.

Brushless motors are smoother, more reliable and capable of generating more torque than the original brushed motors, using an AC voltage supplied to the stator (the stationary part of a rotary system) to create a rotating magnetic field which in turn acts on a magnetic rotor to create mechanical drive.

Put simply – a micromotor is turning electrical energy into mechanical energy in order to drive the surgical handpiece.

Smaller is better

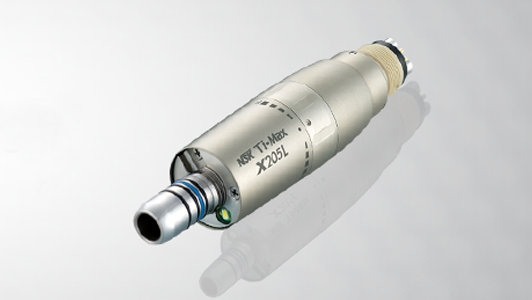

The first electric micromotors were large and heavy by today’s standards but as technology advanced especially in the early 2000s, smaller, lighter three phase brushless motors became commonplace, delivering the same controlled performance in a much smaller package.

The launch of the NSK NLX nano was the big leap forward in shrinking the motor and going brushless; a powerful, lightweight micromotor that can be fully integrated into the delivery system of most new and existing dental chairs. Designed to minimise weight and size to improve the balance of the instrument and motor in the hand of the clinician, it is as powerful as traditional micromotors while reducing fatigue during prolonged surgical procedures.

Building on the success of the NLX nano, the NSK Surgic XT Plus and the ground-breaking NSK Surgic Pro have taken performance levels of compact surgical micromotors further still with the Surgic Pro’s fully integrated system introducing the unique NSK Advanced Handpiece Calibration (AHC) to help guarantee accurate speed and torque control. AHC corrects the differences in the handpiece’s condition by minimising the discrepancy between the set torque value and the actual output which helps to improve overall treatment outcomes.

Keeping control

Keeping accurate control of the speed and torque in surgical procedures, unlike older style air motors where control can be a problem, is the key to a surgical micromotor.

Torque is a measure of the turning force of a rotary device such as a dental handpiece. Controlling torque is an important factor because unlike, for example, cutting a tooth and being able to quickly cut through enamel, it’s about driving slowly into bone during surgical procedures such as placing implants using high torque.

NSK surgical micromotors are paired with a reduction handpiece; the more the speed is reduced, the more the torque increases. Speed and torque have an inverse relationship – the faster the speed, the less torque, the slower the speed the more torque.

The setting of the speed of the micromotor is through the unit itself and controlled by a foot pedal. The unit sets the maximum speed and the foot pedal controls where and when the speed is needed.

The foot pedal contains a small magnet and sensor and as the magnet is pushed down it acts on the sensor like a throttle, effectively telling the motor what to do. Pushing hard on the foot peddle will take the unit up to the maximum set speed (and no further) and as the force is reduced, the speed will drop down accordingly. This means the clinician is free to set the speed and torque recommended by their chosen implant provider or match their particular choice of surgical kit.

Enhanced performance

The NSK Surgic Pro surgical micromotor has been at the forefront of implant and oral surgery and has become an essential piece of equipment clinicians rely on day in, day out. Now NSK has launched the Surgic Pro2 designed to enhance the performance of the Surgic Pro with a range of new specifications to ensure greater comfort, efficiency and safety during implant treatment and oral surgery.

One of the fundamental design changes to the original Surgic Pro is Bluetooth connectivity making the Surgic Pro2 a central interface for other primary surgical applications. By installing a dedicated app and connecting an iPad to the control unit enables real-time display of detailed procedural data such as rotation speed and torque range.

Data can also be displayed and saved when connecting with the Osseo 100+ to measure implant stability and osseointegration to support decisions about when to load an implant.

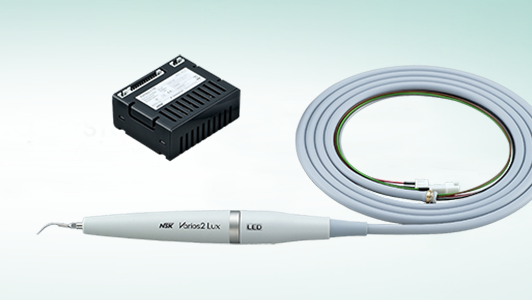

The Surgic Pro2 can be easily linked with the NSK VarioSurg3 ultrasonic surgical unit via Bluetooth with a new wireless foot control making it easy to switch between the two for improved flexibility and workflow. All treatment-related data generated during procedures can saved to an external device and transferred and stored as required in the electronic patient file while also providing full traceability of procedures to aid compliance.

The lighter, more compact motor of the Surgic Pro2 also works to alleviate stress and fatigue during prolonged surgical procedures. While it retains the balance and performance of the Surgic Pro, being both shorter and lighter allows the centre of gravity to be over the hand and away from the wrist for easier handling. This in turn reduces the risk of repetitive strain injuries for the operator which ultimately is better for long term health.

The brains behind the operation

In today’s dental practice the surgical micromotor has effectively evolved to become the ‘brains’ behind successful oral and implant surgery, providing ultimate control to meet the exacting demands of surgical procedures while taking safety and accuracy to a new level.