A young dentist’s guide to electric handpieces and air turbines

NSK’s Graham Brown looks at the two handpiece options available for cutting dental preparations

Despite the influx of digital technology into the dental arena over recent years, dental handpieces remain the essential tools of our trade. Having evolved through a long history of manufacturing expertise, today’s handpieces are high performance, precision instruments that are constantly being refined and improved as technology advances.

There is a bewildering choice of handpieces, especially for those just starting out in their dental career, with variations in quality, price, durability, size and after-sales support depending on your choice of manufacturer and model.

That’s why it is useful to have a good grasp of the options available when starting work so you can feel comfortable and confident in the handpieces you are using on a daily basis.

The high speed options for cutting preparations

The two main types are air turbine and electrically-driven speed increasing contra-angle handpieces. When comparing the two, the key factors are speed, torque and control.

Air-driven turbines contain a cartridge (turbine) that generates high speed rotation. These handpieces are powered by compressed air via the treatment centre and can reach rotation speeds of up to 450,000 rpm.

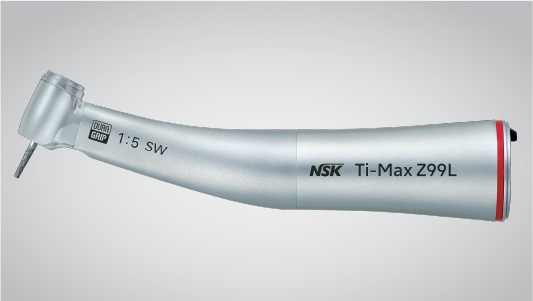

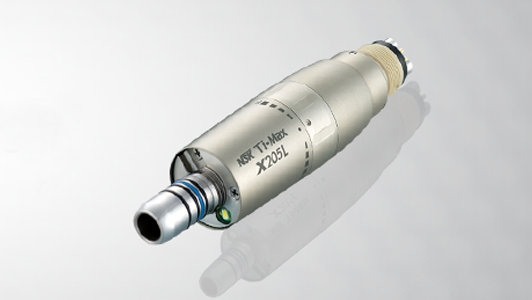

Electric handpieces (speed increasing contra-angles) are powered by an electric micromotor, making the handpiece capable of producing a consistent bur rotation speed of up to 200,000 rpm, which operates at a constant torque cutting through materials far quicker and therefore saving time.

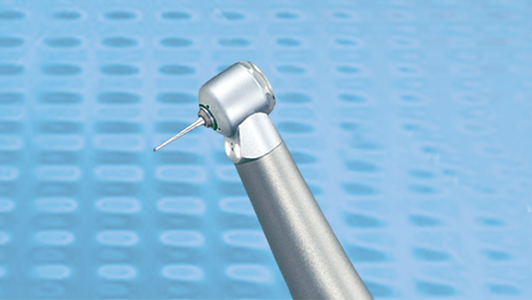

Both types are used for the rapid removal of enamel and dentine, to prepare cavities for restorative procedures, remove tooth structure and to create margins. When used for high-speed preparation and to prevent overheating of the pulp and the bur, they incorporate a water spray to act as a coolant. Water delivery can be via a single port, or multi-ports (up to four) which offer more efficient cooling to facilitate a higher cutting rate and to clear debris from the cutting site.

Air turbines

Thanks to continuing research and development, the latest generation of air turbines deliver unprecedented cutting performance. NSK’s new Ti-Max Z990L turbine for example can deliver between 30 and 44W of power (with air pressure at 3 to 4.2 bar), enabling the turbine to perform extremely efficiently, even when cutting hard materials such as zirconia.

A turbine working at high speeds needs to be light, well-balanced and feel good in the hand. The Ti-Max Z990L and Z890L are designed with an ergonomic body shape, lightweight titanium casing with a textured coating (Duragrip) that reduces hand fatigue and makes the handpiece easier to hold, even when wet.

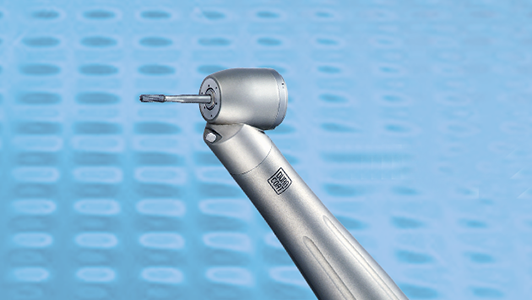

The Ti-Max Z890L and Z micro both have smaller head sizes, which is ideal for posterior access or when working with patients who have a limited mouth opening. This smaller head helps to create more space while improving access and visibility throughout the oral cavity.

‘When you’re prepping teeth towards the back of the mouth with a longer bur, the small head just gives you a couple more millimetres to manoeuvre the handpiece and improve the preparation.’ – Alex Jones, clinical director and dental surgeon, The Campbell Clinic, Nottingham

Electric handpieces

Speed increasing contra-angles have gears and are driven by an electric micromotor. Most perform at a ratio of 1:5; ie if the motor is running at 40,000 rpm, the bur speed can reach 200,000 rpm. With a touch pad, the dentist is in total control by setting the speed appropriate to the nature of the job in hand.

An electric-driven, speed increasing contra-angle provides consistent torque from the micromotor that does not decrease with resistance and high load, giving the clinician greater tactile feedback. Operating at reduced noise levels and with less vibration than turbines, a contra-angle facilitates a smooth, precise cutting action, and that precision makes it an essential tool for prepping for digital dentistry and helping phobic patients.

‘The Ti-Max Z95L is really fast at cutting and removing old crowns but then you can slow things right down for delicate and precise re-preps and final polishing of fine margins.’ – Joe Watson BDS, MSc (Implantology), MFDS RCPS (Glas), Tiwari Watson Dental Care, Glasgow

Speed increasing contra-angles are proven to generate fewer aerosols than turbines and NSK’s Z95L incorporates a two-way spray function. This enables clinicians to swap between traditional spray (water/air mix) or water jet only, controlled by a simple switch at the base of the handpiece.

The same switch offers an additional advantage on the Ti-Max Z45L, which features a 45° head, making it also ideal for chairside minor oral surgery giving better access to the back of the mouth. The switch turns off the spray air, leaving a water jet only, which helps to prevent subcutaneous emphysema.

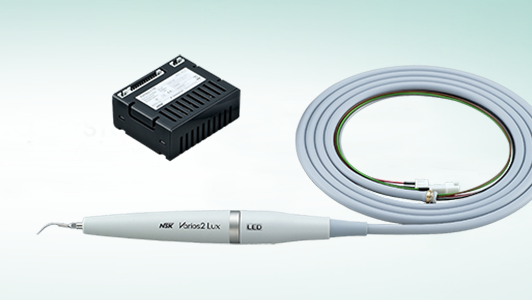

The electric micromotor, which is needed to drive speed increasing contra-angles, can be incorporated in three ways. Firstly, it can be built into a new treatment centre by simply specifying with the manufacturer or it can be retro-fitted into most existing chairs by a qualified engineer. Alternatively, a portable micromotor unit can be used. This easily connects to an existing hose on the cart, which provides coolant air/water from the dental unit and uses the existing foot pedal.

Making the choice

Numerous attributes, including speed/torque, size, weight and noise level can determine the type of handpiece most suitable for different dental procedures. Your type of practice, whether it’s general restorative dentistry or a specialty, may determine the type of handpiece you ultimately choose.

Before you decide, and the decision can be to use both types of technology, talk with a company such as NSK which is a global leader in handpiece manufacture, and take advantage of the local Product Specialist support. Try out your choices, make your decision and implement the care and maintenance advice to maximise the life of your handpieces.

For more information on NSK handpieces and micromotors and to compare options visit mynsk.co.uk/handpieces/