Keep it SMART

Mark Beckwith offers advice on the SMART way to clean, lubricate and sterilise dental handpieces.

Handpieces are one of the most used and valuable tools in the dental surgery. However, they are also routinely contaminated with saliva, blood and biological residues.

This makes any handpiece a potential transmission risk of a host of bacterial and viral infections unless they are decontaminated and maintained with suitable care after every use.

Possibly one the most notable consequences of the pandemic has been that people are now more alert to the need for infection control than ever before. This is positive news as it means a far greater awareness of disease transmission and the need to find ways to make dental treatment safer for patients and staff alike. The most significant way to achieve this is to look at the necessary steps in how best to clean, lubricate and sterilise hollow instruments and handpieces and by using the right choice of autoclave, achieve effective sterilisation.

Be SMART inside and out

Be SMART inside and out

An effective handpiece decontamination protocol offers a safer, more measured

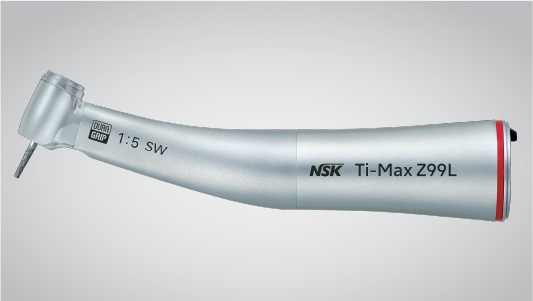

and cost-effective process, one that is reproducible and time-saving. That is why NSK, who manufactures a wide range of dental handpieces and decontamination equipment, has developed the SMART3 approach of 1. Cleaning 2. Lubrication 3. Sterilisation.

Cleaning

Cleaning is about ensuring the surface of handpieces and instruments are free of any residues so that sterilisation can be effective. Any remaining contaminants will act as a barrier to steam penetration, therefore all contaminants on the external surfaces should be removed immediately after use.

This can be done manually, under cold running water using a soft to medium, non-metallic brush. Surfaces should then be disinfected with a good quality disinfectant wipe. Any residue should be rinsed off under cold running water in a separate cleaning sink, then dried with a clean paper wipe. After a careful, visual inspection, they are ready to be cleaned internally.

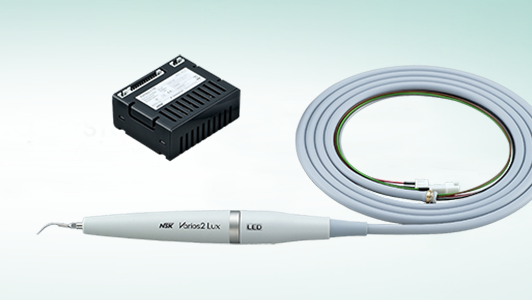

Cleaning the internal surfaces and hollow channels (lumens) of handpieces presents something of a challenge. Effective cleaning of both the external and hidden internal surfaces is best achieved using a dedicated handpiece cleaning and lubrication unit such as the NSK iCare. An automated system uses solutions designed to quickly and effectively remove any contaminants from the internal workings and deliver the precise amount of lubrication to all parts of the mechanism, including internal lumens, in preparation for subsequent sterilisation. This should always be carried out in accordance with the handpiece manufacturer’s guidelines.

Lubrication

Manual lubrication of a handpiece can be tricky and relies heavily on the diligence of the operator to ensure the proper steps are taken. An automated cleaning and lubrication unit dispenses the precise amount of lubricant every time. With connection to a source of compressed air, any residual contaminants, solutions and lubricants that could compromise sterilisation are automatically purged from inside the handpiece at each stage of the cycle in just seconds in one measured and reproducible process.

Sterilisation

Steam sterilisation is the essential next step after cleaning and lubrication for the reprocessing of handpieces and instruments. This process breaks the chain of potential cross-infection between patients by killing microorganisms, including any viruses, bacteria and fungal spores that may otherwise cause infection or disease.

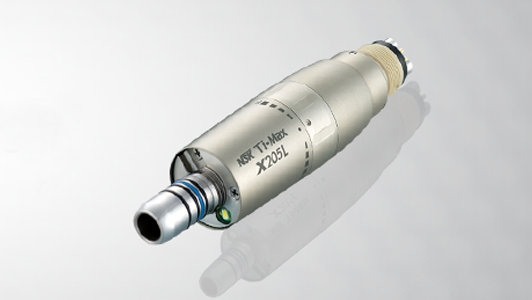

The recommended method of sterilisation of hollow handpieces such as turbines and contra-angles, is by using the correct, validated autoclave cycle that delivers saturated steam, under pressure at the highest temperature compatible with the load, typically 134-137° for at least a three-minute holding time.

Sterilisation requires direct contact between saturated steam and every internal and external surface of the instrument. However, because of the complexity of hollow instruments, including handpieces and pouched loads, effective steam penetration and sterility will be compromised by the presence of air within the instrument

or sterile packaging. Therefore it is imperative all air is actively removed from the chamber and load when processing anything other than solid, unwrapped instruments (ref: HTM 01-05: 4.5).

A handpiece that has been correctly cleaned and lubricated and excess solution and lubricant is purged from the instrument prior to sterilisation, as long as all the air has been removed, steam will be able to penetrate the instrument and take it through a sterilisation process. This is why an appropriate S or B type vacuum autoclave cycle, rather than a non-vacuum Type N cycle, must always be used to sterilise handpieces.

Type S autoclave cycles are designed to take specific loads through a sterilisation process including handpieces and pouched instruments where stated. They use vacuum-assisted, active air removal and should only be used in accordance with the manufacturer’s instructions.

Type B autoclave cycles meet a defined standard (i.e. EN 13060) that specifies the performance requirements and test methods for small steam sterilisers and sterilisation cycles. They almost always employ vacuum pumps to effect active air removal and steam penetration, making them suitable to process a wide variety of loads including hollow, air retentive and packaged loads including hollow instruments in sealed packaging.

The sterilisation process can be further improved using a vacuum autoclave that incorporates a copper chamber, such as the NSK iMax S S type autoclave or the advanced iClave plus B type vacuum autoclave. Copper, being more thermally efficient than stainless steel, improves total cycle times for faster throughput while thermo-dynamic drying protects instruments from corrosion, discolouration and re-contamination.

The SMART solution

The NSK SMART3 handpiece decontamination protocol makes the three crucial decontamination steps of cleaning, lubrication and sterilisation safer, measured, affordable, reproducible and time-saving.

Reducing the risk of manual error and inconsistencies by the use of equipment specifically designed for each part of the decontamination process ensures not only that best practice can be achieved but it can be reproduced every single time.