Better solutions for internal handpiece decontamination and maintenance

With infection control now a top priority, David Gibson, Decontamination Consultant, discusses how raising the standards of handpiece re-processing can help improve the life of these expensive instruments, reduce ongoing maintenance costs and help ensure they can be effectively and correctly sterilised, vital in today’s climate.

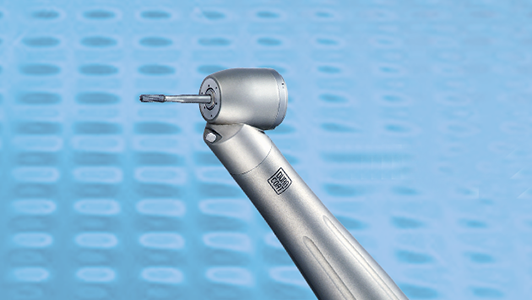

A common challenge for dental practices is the handpieces. Handpieces contain a combination of hollow channels (lumens) and precision-engineered moving parts. As a result, whilst the decontamination of their external surfaces is relatively straightforward, decontaminating and maintaining the internal surfaces is not, particularly when using manual methods and the wrong type of autoclave or sterilisation cycle.

Additionally, if handpieces are to be stored for any length of time, the internal working parts must be completely dry after sterilisation. If handpieces retain moisture for extended periods, the internal parts can corrode causing the handpieces to seize up – a situation that leads to expensive downtime and repairs. It is therefore essential that handpieces are lubricated with a specific volume of oil, immediately after cleaning, prior to sterilisation.

Automated cleaning and lubrication

A manual handpiece cleaning and lubrication process relies on the diligence of the operator to ensure the correct products are used and the proper steps are undertaken.

A manual handpiece cleaning and lubrication process relies on the diligence of the operator to ensure the correct products are used and the proper steps are undertaken.

More importantly, sufficient time must be allowed at the end of each stage of the process for cleaning liquids, debris and lubricating oils to thoroughly drain from the instruments before the sterilisation phase can be implemented. If moisture still remains in handpieces after cleaning, it will result in the emulsification of lubricating oil. If excess oil remains after lubrication, the handpiece cannot be sterilised effectively and it may also result in damage to the autoclave.

The most efficient and cost-effective solution for preparing instruments for sterilisation and to reduce costly maintenance, is to use a professional handpiece oiling and maintenance unit, one that is dedicated to the task. The most effective units are usually made by companies who know how best to look after these complex instruments – the handpiece manufacturer themselves.

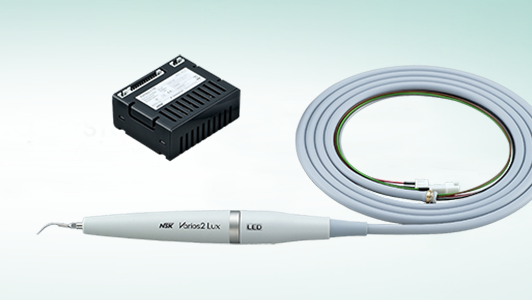

For example, NSK’s iCare delivers measured lubrication for up to four instruments in a compact, fast and effective unit, assuring correct, reproducible lubrication every time. Crucially, it connects to a source of compressed air to facilitate complete removal of moisture, debris and excess oil after lubrication.

By ensuring these essential steps have been taken, you can be certain handpieces are properly maintained and, in today’s climate where the risk of transmission of harmful pathogens is high, can be effectively sterilised thereafter.

Sterilisation

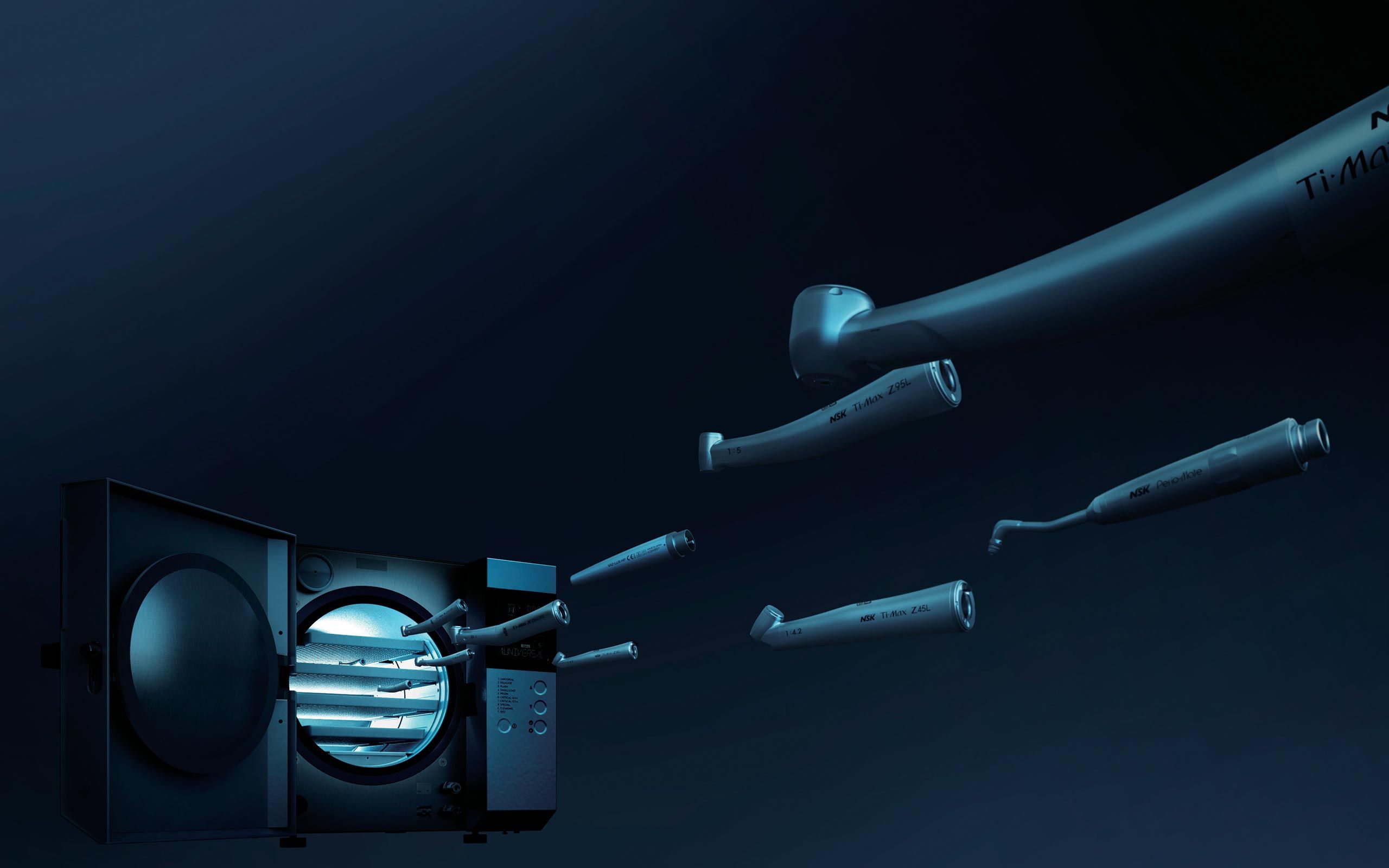

Vacuum autoclaves are the accepted standard in Europe where they are preferred as the daily autoclave of choice. Vacuum autoclaves employ a process of active air removal, using a pump to forcibly remove all the ambient air out of the chamber. This enhanced process, compared with the passive, displacement process used in non-vacuum autoclaves, ensures steam will fully penetrate to all instrument surfaces. This includes internal surfaces of hollow instruments such as correctly lubricated handpieces and instruments which are being sterilised in appropriate packaging.

Vacuum autoclaves are the accepted standard in Europe where they are preferred as the daily autoclave of choice. Vacuum autoclaves employ a process of active air removal, using a pump to forcibly remove all the ambient air out of the chamber. This enhanced process, compared with the passive, displacement process used in non-vacuum autoclaves, ensures steam will fully penetrate to all instrument surfaces. This includes internal surfaces of hollow instruments such as correctly lubricated handpieces and instruments which are being sterilised in appropriate packaging.

Sterilisation performance for handpieces can be further improved by using a vacuum autoclave that incorporates a copper chamber. Copper, being more thermally efficient than stainless steel, offers additional benefits to the user; performance is improved both in terms of cycle speed and drying. Furthermore, improvements to the efficiency of the drying phase help eliminate many handpiece care and maintenance issues, including corrosion and discolouration.

Bringing it all together

NSK has worked for decades to develop decontamination equipment and products to help dental practices maintain the highest standards of instrument decontamination, especially when it comes to handpieces. The iCare handpiece oiling and maintenance unit processes 4 handpieces at a time, to prepare them for effective sterilisation. There is also the iCare+ decontamination unit, which adds an extra step of disinfection and is proven to provide enhanced protection including against Covid-19 viruses when used with the n.cid bactericidal, fungicidal and virucidal disinfection solution. Using these as an integral part of your overall decontamination process will help ensure the NSK iMax S and iClave plus vacuum autoclaves with their advanced copper chamber technology are capable of effectively sterilising handpieces to the highest standards.

Find out more about NSK’s wide range of decontamination equipment here…